The model accounted for reaction mechanism and kinetics in vapor & liquid phases both in the absorber as well as cooler- condenser. The heat transfer coefficient s we recalculated rigorously using application software and were plugged into the model to have integrated analysis.”…. We feel that without such a robust process model, it would have been really difficult to study so many variations, like trade-offs between operating and capital costs….”

Project Manager, Client Some of the key performance parameters which were optimized after various runs were:- Nitric acid concentration

- Production

- NOx at the absorber outlet

- Specific ammonia consumption

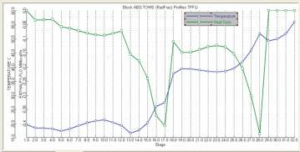

Phase one of the study conclusively indicated a sizable deficit in the capacity under the new operating conditions. Thereafter, the second phase of the project was undertaken to locate the bottle-necks in the process and work upon a strategy to achieve the required capacity from the plant.

Phase one of the study conclusively indicated a sizable deficit in the capacity under the new operating conditions. Thereafter, the second phase of the project was undertaken to locate the bottle-necks in the process and work upon a strategy to achieve the required capacity from the plant. The client’s strong experience in the field also brought out interesting operating strategies that were tested and validated using the tuned plant model. Some of the interesting solutions were:

- Use of different cooling utilities in the absorber to optimize the chilling unit capacity

- Reducing the inlet air temperature

- Change of air to ammonia ratio

The study recommended a combination of operating conditions along with a few new types of equipment, to meet the objective of getting the rated capacity of 280 TPD in Indonesia.

The approach to technology application encouraged end-client to review their plan on Operator Training Simulator (OTS) & Advanced Process Control (APC) – to fully exploit the effort and power of the model that has been developed in this project.

Challenge:

Old Nitric Acid plant being relocated from the USA to Indonesia –

- Validate the existing plant capacity

- Predict the existing plant performance level sat the new location

- Suggest operating parameter changes for capacity increase with the business objective of throughput, quality & NOx emission levels being met

Solution:

Build a detailed model of the complete plant including Columns, Reactor, Heat exchangers, Compressor, etc.

Learning:

- The ambient air and cooling conditions have a significant impact on the plant capacity

- Novel operating strategies had the potential of reducing new capital investments

Benefits:

- The existing plant load was validated

- Capacity at the new location was predicted

- Various scenarios were simulated for capacity increase

- Ensured that the client gets the rated production at the new location