e-SEEMA©

Regulatory requirements regarding SOx, NOx & CO2 emissions are getting stricter day by day. Process industries are increasingly forced to think of ways & means to monitor & record their stack emissions, ideally in real time through on-line data/analysis. From a plant owner’s perspective, it is important that efficient and reliable tools for acquiring emission data are available.

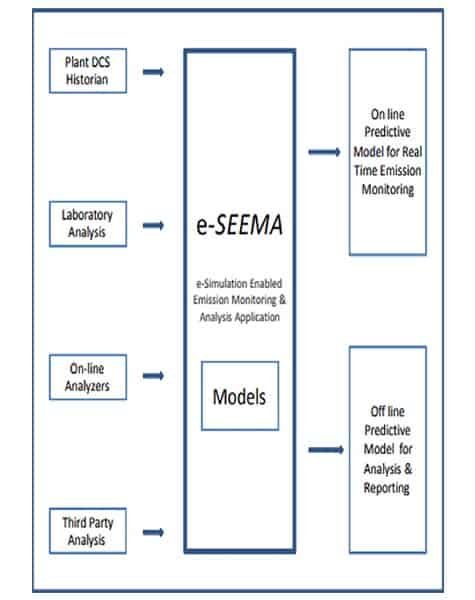

The above needs are addressed by e-SEEMA™ (e-Simulation Enabled Emission Monitoring & Analysis), a first principle-based simulation enabled application to calculate, record, analyze, and monitor the SOx, NOx, and CO2 emission. Also, it can help to determine analyzer deviations/errors and validate measurements by third party inspection agencies.

e-SEEMA™ provides an online predictive model for real-time emission monitoring & an offline predictive model for analysis & reporting.

Due to huge emissions, it is essential for process industries to adopt a holistic approach of tracking, analyzing & reporting SOx, NOx & CO2 emissions through a model based business process leveraging first principle simulation, data based inferential, online analyzers, third party inspection data to comply with regulatory norms.

Monitor, validate, analyze and report SOx, NOx & CO2 emissions for:

- Regulatory compliance

- Furnace performance analysis

- Online analyzer performance management

Implement e-SEEMA™, to monitor and report SOx, NOx & CO2 emission which allows user to analyze furnace and stack performance. It also calculates other important parameters like:

- Flue gas oxygen content

- Stack volumetric flowrate

- Stack velocity

- Dewpoint calculations

- Flame temperature

- Perform data reconciliation to know any consistent analyzer deviation

- Validated sound basis for reporting & analysis of SOx, NOx & CO2 emissions

- Perform analysis for the all the stacks in the plant on daily basis

- Validate the measurements of third party inspection agencies

- Perform quick calculations using inferential techniques based on plant operating data