What is the Blending Process in the Crude Oil Refinery?

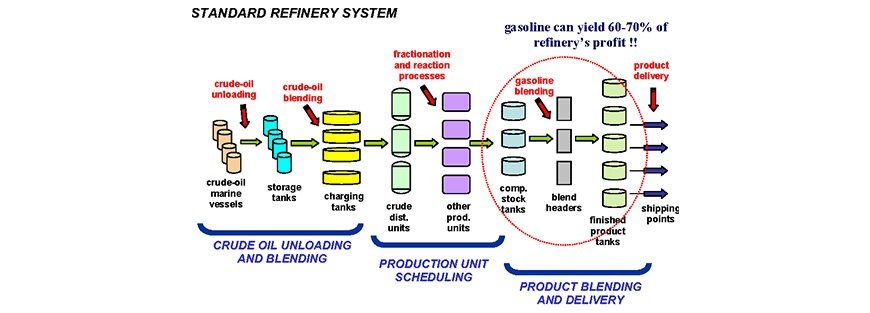

Crude oil needs to be processed in a refinery before it can be used. There are three major types of operation that are performed to refine the oil into finished products:

- Separation

- Conversion

- Treating & Blending

Blending is the last step in the refining process that mixes the optimal combination of components (among various petroleum streams) to produce the final finished product. Blending is much more complicated than a simple mixing of components.

Modern automotive fuel may have come from as many as 15 different hydrocarbon streams, each of which has an impact on the final specification and overall cost. It is one of the most critical economic issues for both traders and refiners.

- Crude Oil blending:

The main purposes of crude oil blending are to optimize commercial value, to upgrade or reduce oil consumption to meet specifications, and to facilitate oil movement. Simulation software, such as linear programming modeling, is often used to estimate the rate components that provide a low-cost mix. Generally, crude oil blending takes place before crude arrives in the refinery. The optimization of crude oil blends and the maximization of low-cost refinery intermediates in final blends are the basic processes for achieving this goal of using cheap crude oils. The highest degree of blending optimization requires continuous updating of the simulation model by adapting to real-time analytical trends.

- Products blending:

All refineries need to meet tight product specifications in the form of ASTM temperatures, Viscosities, octane numbers, flashpoints, pour points, etc. To achieve desired products with minimum specifications of these important parameters, blending is carried out. There are four product blending pools in a typical refinery.

- LPG Pool: This pool allows the blending of saturated C3s and C4s to generate C3 LPG and C4 LPG

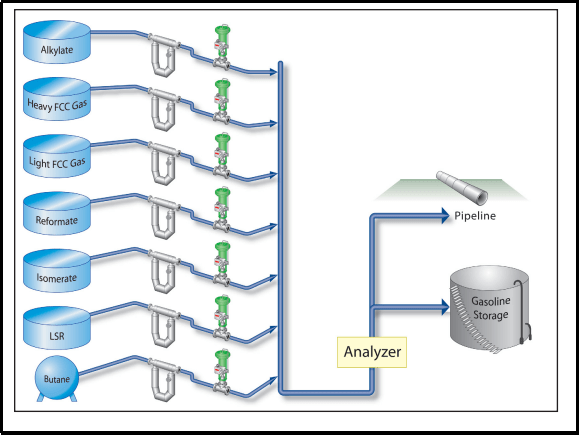

- Gasoline Pool (Premium + Regular): The most important blending pool in the refinery complex is the gasoline pool. Premium and Regular gasoline products are prepared by blending appropriate amounts of n-butane, reformate, light naphtha, alkylate and light cracked naphtha. These two products are by far the most profit-making products of the modern refinery. An emphasis is there to maximize their total products while meeting the product specifications

- Gas Oil/Diesel Pool: The gas oil pool produces automotive diesel and heating oil from kerosene (from CDU), LGO, LVGO, and slurry

- Fuel Oil/Bunker Oil Pool: In the fuel oil pool, haring diesel, heavy fuel oil, and bunker oil are produced from LVGO, slurry, and cracked residue

- Types of Blending Processes:

Products can be blended by different processes, such as

- In-line through a manifold system

- Batch blending in tanks

- Onboard blending into marine vessels

Each of these processes has its own benefits and challenges along with the individual expertise needed to make them work efficiently.

- The in-line blending of gasoline, distillates, jet fuel, and kerosene is accomplished by injecting proportionate amounts of each component into the main where turbulence promotes thorough mixing. Additives including octane enhancers, metal deactivators, anti-oxidants, anti-knock agents, gum and rust inhibitors, detergents, etc. are added during and/or after blending to provide specific properties not inherent in hydrocarbons

- In- Blending – all component is fed into mixing and stirred until a homogeneous blend is achieved

- Onboard blending offers many advantages to suppliers and trading organizations, allowing you to prepare cargo to the required specifications without the need for onshore facilities

Please click here to explore our menu of CAM Application.