Industry: Power

Business Area: Engineering Design Review – Burner Management System (BMS)

Background:

A major Power producer located in Middle-East was building a new green field power plant (2640 MW) with boiler fuel being Heavy Fuel Oil, Heavy Crude Oil. As part of engineering integrity validation, a third party certification major was contracted for design review and certification.

Business Objective:

Design Review for Safety of Burner Management System for Boilers, as per NFPA-85 standard.

Solution:

Design review of the safety of burner management system for Boilers, as per NFPA -85 Boiler and Combustion Systems Hazards Code Edition 2011.

| NFPA 85 – 2011 List | |||||||||

| Sr. No. | Cl. No. | Sub Cl. | The requirement to be Specified | Details of Compliance | Document Reference | Evidence of compliance | Remarks | Engg Company Remarks | |

| Brief Description | Applicablity | ||||||||

| 6.3 | Mechanical equipment Requirements | ||||||||

| 6.3.1 | General requirements for mechanical equipment shall be in accordance with Sections 4.6 through 4.16. | Y | |||||||

| 6.3.2 | Forced draft (FD) and induced draft (ID) .fans shall include all fans whose purpose is to supply air for combustion or remove products of combustion, including associated booster fans, and exclude fans in the pulverized coal system. | Y | |||||||

| 6.3.3 | 6.3.3.1 A header safety shutoff valve and individual burner | Y | |||||||

| safety shutoff valves shall be provided. | |||||||||

| 6.3.3.2 Proof of closure shall be provided for all header and | Y | ||||||||

| burner safety shutoff valves. | |||||||||

| 6.3.3.3 Multiple burners supplied from a common set of | Y | ||||||||

| burner safety shutoff valves shall be treated as a single (indi- | |||||||||

| vidual) burner. (See 6.6~7.1.3 and 6.7.7.1.3 for tufo-burner units. ) | |||||||||

Approach:

The study covered document review and compliance of various sections of BMS including:

- Boiler System Design Definition

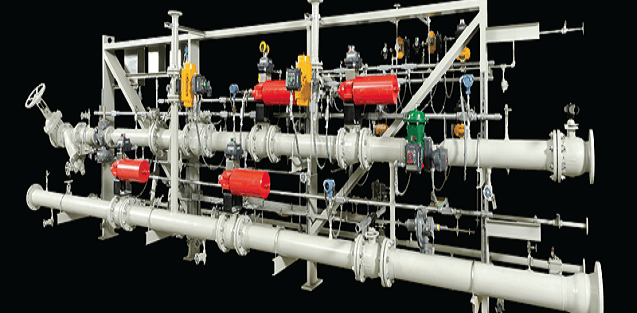

- Piping& Instrumentation Diagrams

- BMS Control Philosophy

- BMS& Protection logic

- Piping design criteria

| DOCUMENT CONTROL INDEX | |||||||||

| SL No | DRAWING / DOCUMENT | DESCRIPTION | Action Markup | No of Sheets | Doc. Revision | Doc. Received Date | DAD Issue No. | DAD Date | Doc status |

| 1 | MSC-KO-4-1-3-03 (Mitsubishi document) | Control philosophy and control criteria fundamentals | IN | 44 | 1 | 11.04.14 | |||

| 2 | 10-CAD-1-18-001-001 | Control logic diagram for BMS and UPS | VI | 105 | 1 | 11.04.14 | |||

| 3 | 01-HH-S-20-001-001 | P&I Diagram for boiler burning system (D.O for warmup) | VI | 1 | 5 | 11.04.14 | |||