The primary goal of a process designer is to design an exchanger with the required thermal duty with the LOWEST COST yet provide EXCELLENT IN-SERVICE RELIABILITY. Allocation is an important decision in this process. Usually, common sense is a reliable guide when deciding which fluid belongs on the shell side and which on the tube side. The following considerations have a strong influence in deciding the allocation.

Fouling Tendencies (Clean/ Dirty)

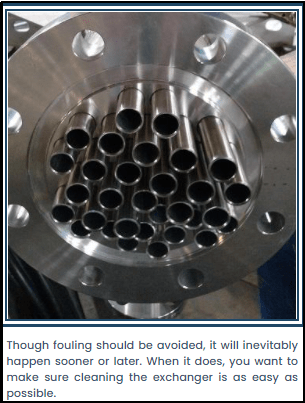

Fouling on tubes greatly reduces the thermal performance of the heat exchanger. Also, fouling causes an increase in the pressure drop. In exchangers handling DIRTY FLUIDS, or streams that are otherwise likely to cause fouling, the exchanger design is dominated by features which seek:

- To minimize fouling (e.g. high velocity, avoidance of dead or eddy flow regions)

- To facilitate cleaning (fouling fluid on tube-side, wide pitch, and rotated square layout if the shell-side fluid is fouling)

- To extend operational life by multiple units

Exchangers subject to fouling or scaling must be cleaned periodically. It is easier to clean the tube side than the shell side. Sometimes you can just open the ‘head’ of the exchanger and hydro-blast each tube, instead of having to remove the entire tube bundle out of the shell. Also, the inside of tubes is an easier surface to deal with than the complex surface of the tube bundle outside and shell inside. The shell is harder to clean mechanically and chemical cleaning is usually the only option.

Therefore, it is preferred that any fouling/ viscous/ solid-carrying/ dirty streams go into the tube side. As the allowable velocity in the tubes is usually higher than at the shell side and a high fluid velocity causes attrition of the deposits, it is possible to reduce fouling by design. In a fixed tube sheet exchanger, the cleaner fluid should be on the shell side and the dirty fluid which is likely to cause fouling should go on the tube side.

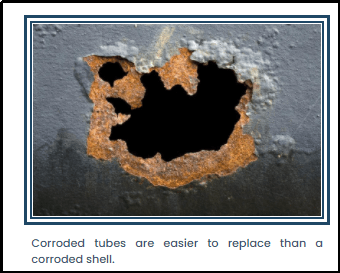

Corrosion

Corrosive fluids can cause severe damage to the heat exchanger. Corrosive services demand for use of expensive, exotic metals that can withstand corrosion better than plain old carbon steel. Generally, the corrosive fluid will be placed in the tubes so that at least the shell need not be made of corrosion-resistant material. Only the tubes, tube sheets, heads, and channels require the corrosion-resistant alloys.

If you put a corrosive fluid on the shell side, you would need to use the corrosion-resistant material on both the shell side and tube side. If the corrosion cannot be effectively prevented but only slowed by choice of material, a design must be chosen in which corrodible components can be easily replaced. Cooling is generally kept on the tube side because it tends to corrode carbon steel and form scale.

Containment of Expensive/ Lethal/ Toxic/ Hazardous Fluids

‘Critical’ fluids (i.e. Expensive/ Lethal/ Toxic/ Hazardous) should be positively contained to prevent leaks. This means that heat exchanger designs that feature girth flanges or floating heads, the shell side is not a suitable location for such critical fluids because the risk of leaks is too high. Such fluids should therefore normally go on the tube side. Exchangers featuring all-welded construction can safely carry hazardous fluids on the shell side, though you should remember the difficulty of cleaning the shell side.

Physical State of Fluid (Liquid, Gas, Mixture)

The shell side tends to be preferred for services with phase changes. The shell side offers a larger cross-section for vapor flow, and hence lower pressure drops. Process vapors to be condensed are therefore normally placed on the shell side, though the tube side is generally used for condensing steam.

Operating Pressure & Temperature

Extreme pressures and temperatures (high or low) can increase the metal thickness or cost of the materials of construction required. If one of the streams is at a high pressure-temperature, it is desirable to put that inside the tubes because they are likely to require a greater metal thickness or more expensive materials of construction. The tubes, being smaller in diameter than the shell, withstand higher pressures. In this case, only the tubes and the tube-side fittings need to be designed to withstand the high pressure, whereas the shell may be made of lighter-weight metal.

Allowable Pressure Drops

Streams with low allowable pressure drop should usually be placed on the tube side because tubes facilitate a streamlined flow, lower turbulence. HIGH VISCOSITY OR LOW FLOWRATES To obtain an economic design, high heat transfer coefficients are required. As the heat transfer coefficients are much higher for turbulent flow this is the most important aspect to look into. For a highly viscous medium or a low flowrate turbulent flow can be obtained easier at the shell side. If the Reynolds number at the shell side is below 200, however, it will probably be cheaper to allocate this fluid to the tube side and use a high number of tube passes to increase the velocity and turbulence. The baffles on the shell side help to ensure good mixing, which reduces the effects of laminar flow and therefore tends to increase heat-transfer coefficients. Hence, you will get better heat transfer if viscous fluids are kept on the shell side.

Fluid Velocity

Fluids that need to be kept at a consistently high velocity, such as or propylene glycol for cooling, should be kept on the tube side. High speeds increase the heat transfer coefficient but are associated with potential pressure drop. Another advantage of high speeds is reduced tube fouling, which increases the thermal transfer as well.

Low Heat Transfer Coefficient

If one has an inherently low heat transfer coefficient such as low-pressure gases or viscous liquids, this is preferentially put on the shell-side so that an extended surface may be used to reduce the total cost of the heat exchanger. Finned tubes can be used to increase the effective surface area the shell-side fluid sees, letting you increase the heat transfer effectiveness on this side. Crossflow gives higher heat transfer coefficients than in-plane tubes, hence put fluid with the lowest heat transfer coefficient on the shell side. Viscous fluids require a judgment call. Placing the more viscous fluid on the shell side will improve heat transfer but using the tube side will lead to a lower pressure drop. There are more variables you can “play” within the shell side, allowing you more options to deal with high-pressure drops or low heat transfer coefficients and to target certain values more precisely. For example, tube baffle support spacing can be changed in small increments. This flexibility tends to favor putting the fluid with poor heat transfer properties on the shell side. With the tube side usually, all you can do is alter the number of tubes passes to an even number (2, 4, 6, etc.).

Going from 2 to 4 passes will roughly double the velocity and increase the pressure drop by a factor of eight. (ΔP is proportional to Length and Velocity squared and doubling the tube passes doubles both L and V values) Film resistance / laminar flow is more easily overcome on the shell side. The shell side tends to experience vortex shedding and rapid changes in direction due to tube support baffles. These factors promote mixing between “layers” of fluid. This means that often, from a heat transfer perspective, you would prefer to put viscous fluids in the shell-side Twisted tubes, static mixers or tube inserts increase turbulence, and thus heat-transfer coefficients on the tube side by reducing the effects of laminar flow.

Thermal Expansion

Thermal expansion may be an issue if one of the fluids undergoes a temperature change of more than 150°C. In such a case, you would normally put the high-temperature change fluid on the shell side, which is better able to handle large temperature changes in certain exchanger designs. In summary, the fluids preferred on the tube side are the following:

- Fouling, erosive or corrosive fluid

- Toxic, Lethal, or valuable fluid

- Fluid at a higher pressure

- Hotter fluid

- with a less available pressure drop

- Less-viscous fluid

- with smaller volumetric flowrate

- Cooling

In summary, the fluids preferred on the shell side are the following:

- Viscous fluid

- Fluid with a higher flow rate

- High-temperature change fluid

While deciding the fluid allocation, many trade-offs are made in heat transfer coefficients, pressure drop, fouling tendencies, etc. None of the suggestions above are definitive, use them as a starting point.

Please click here to explore our menu of TACIT services.