Industry: Refining & Petrochemical

Application: Feedstock Planning

Background:

An Integrated Refinery & Petrochemical Asian Major, used best-in-class software application with supporting business processes for feedstock evaluation, planning & execution.

Business Objective:

A Root Cause Analysis of Plan Vs Actual data, highlighted the gaps of how the best in class in class applications needed to be utilized via the “Integrated Analytics” approach to reduce the gap of Plan Vs Actual.

Solution:

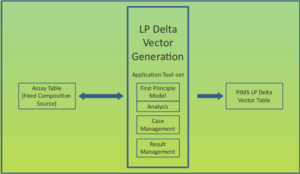

Development of “Application Tool-set” (a Validated & Calibrated Process Model being the core engine) coupled with supporting Business Process to enable the generation of LP Delta Vectors for applying in the LP Planning Model built in Aspen PIMS.

Approach:

Leveraging the Operating Data & Test Run data as available from a Real-Time Database along with Design data, a first principle integrated process model was developed, validated & calibrated. Subsequently, various step out cases with different feed compositions (15+) & operating conditions as required for LP data generation was run, analyzed & integrated with the LP model.

Primary Distillation – Model Structure

Table CRDCUTS

| TEXT | TYPE | C11 | C12 | C21 | C22 | |

| GAS | Off gases | 1 | 1 | 1 | 1 | 1 |

| LN1 | Light Naphtha (NCC) | 1 | 1 | 1 | 1 | 1 |

| LH1 | Lt./ Hy Swing | 4 | 1 | 2 | 3 | 4 |

| HN1 | Hy Naphtha (Ref) | 1 | 1 | 1 | 1 | 1 |

| NK1 | Nap/Kero Swing | 4 | 1 | 2 | 3 | 4 |

| BTM | Rerun Column BTMS | 1 | 1 | 1 | 1 | 1 |

| KE1 | Kero/ Jet | 9 | 1 | 1 | 1 | 1 |

| HY1 | Kero Splitter BTMS | 9 | 1 | 1 | 1 | 1 |

| HE1 | Hy End (solvent) | 9 | 1 | 1 | 1 | 1 |

| HY2 | Hy End Splitter BTMS | 9 | 1 | 1 | 1 | 1 |

As part of Solution Sustenance, an easy-to-use “Application Toolset” was developed & delivered for use by the LP team (less experienced on Process Models) to enable extraction of Process Model results in formats consistent with LP model requirements. The Application toolset also enabled handling independently of the delta vector generation for additional similar or new feedstocks.