LNG Plant Dynamic Model helps ease operations for a South–East Asia client

A LNG, Liquefied Natural Gas, plant purifies and liquefies natural gas to make it practical and commercially viable for transportation from one country to another. There are many i-censed/proprietary refrigeration technologies that make it possible to cool the gas down to approximately -160° C. This process also requires very strict safety measures and controls during all liquefaction stages, due to the highly vulnerable and flammable nature of the gas involved.

A large LNG producer in South East Asia, that collects natural gas from various offshore fields to produce LNG mainly for electric companies in the Far East, undertook a key initiative to improve its operational efficiency. It was a first of its kind initiative ever since the plant went on-stream in 1995.

The customer decided to build a full scale integrated dynamic simulation system for the LNG plant. The objective was to build a system that is accurate enough for engineering studies and yet fast enough for operator training purposes.

An integrated dynamic model helps plant engineers and operator simulators to understands the process industries involved & thereby empowering the operator to handle the upset situations in a quicker, efficient, and safest manner.

Modeling the unit:

All the relevant datasheets, process descriptions, standard & emergency operating procedures, and drawings were reviewed and analyzed for the data required for building the dynamic model. Keeping the data gaps, project schedule, and the end-use of the model in mind, it was decided to target a model matching design and operating data within +/- 5% but lean enough to run in real-time.

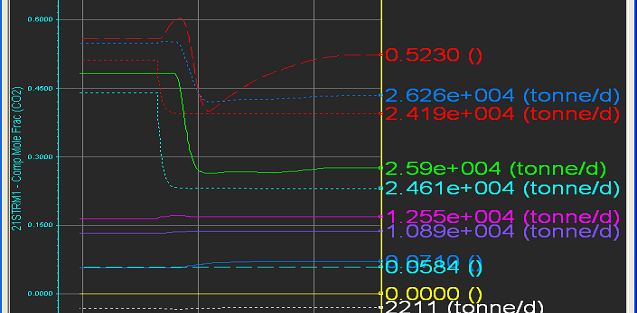

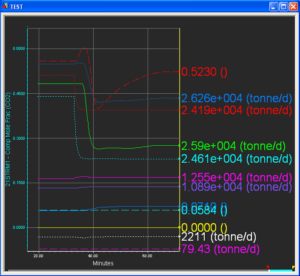

The heart of the model is the Main Cryogenic Heat Exchanger (MCHE) that mainly cools the LNG product. Fine-tuning MCHE was the key to achieving correct performance.

The integrated model was configured for:

- Proper control response

- H2S, CO2 removal from the Sulfinol Unit

- Dehydration sequence of adsorption& regeneration

The model was rigorously tested for:

- Plant shutdown &startup

- Recreation of past malfunctions (e.g. failing of an air-cooler fan, loss of cooling water/steam)

- Emergency procedures

Some of the important checkpoints were:

- The behavior of MCHE as per licensor guidelines

- Change of propane refrigeration flow based on production rate & ambient temperature

- Change of LMR (Light Mixed Refrigerant) & HMR (Heavy Mixed Refrigerant) based on desired product outlet temperature

- Matching process parameters as per the DCS dump (graphics)

A team of client engineers and operators performed an actual shutdown & startup of the plant successfully, as part of the Acceptance Test.

Challenge:

To address the engineering and operator training needs of a LNG plant.

Solution:

Develop a detailed dynamic model of the complete plant including:

- Pig Receiver, Slug catcher & Feed Gas Metering Station

- Sulfinol(Acid Gas Removal) Unit þ Dehydration Unit

- Mercury Removal Unit

- LNG Plant Liquefaction Unit comprising of Main Cryogenic Heat Exchanger (MCHE)

- End Flash Unit

- Stabilization Unit

- Steam Condensate Unit

- Sour Gas Incineration Unit

- Fuel Gas System

The model was integrated with the HMI graphics. Standard startup and shutdown etc. were carried out on the integrated model.

Learning:

- The ambient air and cooling water conditions have a significant impact on the LNG production capacity

- Variation of Startup and Shutdown SOPs were also tested on the model

Benefits:

- Replica of an existing plant for real-life training for plant operators

- Use the model to identify capacity expansion bottlenecks

- Improve the model fidelity for more complex engineering studies