Model Predictive Control-Advanced Process Control-Optimization

In today’s economic environment, capital budgets and overhead are constantly being cut. Companies are faced with:

- Global Competition,

- Soaring Energy Costs

- Meeting Production and Quality targets

- Stricter Environmental Regulations

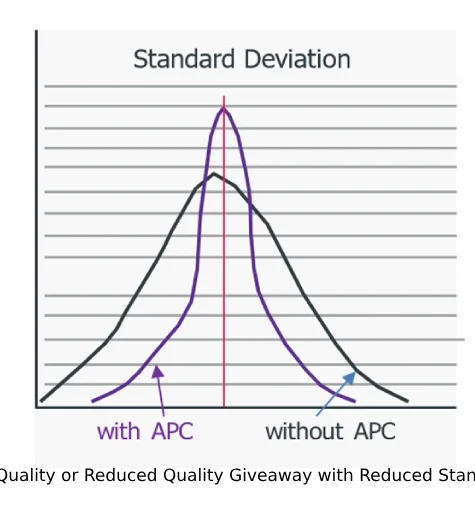

APC or MPC (Model Predictive Control) application improves profitability by enhancing quality or minimizing quality give away, increasing throughput, reducing energy usage, minimizing recycle, maximizing recoveries, reduced specific consumption, minimizing process variability with reduced operator stress-interventions, etc. depending upon process.

Being a closed loop system, APC or MPC technology provides set points to control systems in a real time secure environment enabling realizing best process potential.

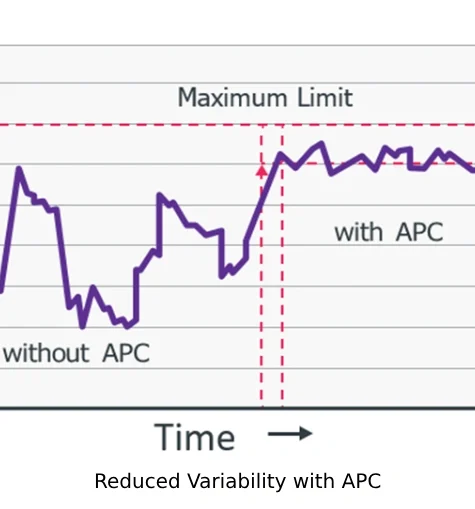

At its core, the Predictive control helps process operations realize their full potential by moving the process closer to active constraints — resulting in reduced process variability and increased profits.

EQNX has successfully implemented APC across multiple industries including- Refining, Chemicals and Power. These projects have been unique and many of them being world’s first OR first in Asian region.

Each project has delivered validated economic benefits and many have been published jointly with customers as a public success story and also being mentioned in the company’s Annual Report for the benefits realized.

Stabilize. Optimize. Maximize- Turn process noise into profit

Increased Throughput-

- Push operating limits safely and consistently

- Plants produce more within existing constraints

- More output without major capital investment.

Improved Product Quality-

- Minimizes variability

- Tighter control over critical process parameters

- Consistent quality- fewer rejects – better customer satisfaction.

Improved Sustainability –

- Optimizes energy through optimal setpoints.

- Reduced fuel- power -water

- Reduced material usage.

Enhanced Process Stability & Operator Support-

- Reduces manual intervention-stable plant across varying conditions.

- Reduces operator stress and fatigue

- Improves safety

Safe Autonomous

Reduced Standard Deviation

Pushing Operations Envelope

Implement APC in your plant- call EQNX today.

A manufacturing plant faces several challenges including-

- Process Variability due to fluctuations in raw material, environmental conditions, equipment performance cause instability

- Higher Energy Consumption and emissions impacting Sustainability due to inefficient control strategies

- Sub-Optimal Operations as operators run process conservatively to avoid violating constraints leading to efficiency losses.

- Revenue loss due to quality inconsistency and off-spec product.

- Operator Dependence and manual control relies heavily on operator skills and experience which can vary.

EQNX has a mature and structured approach to design-implement-sustain-audit APC applications-programs, embedded with Global Best Practices. With a rich experience of APC project lifecycle in diverse industry verticals and cross leverage of other plant digital technologies on diverse platforms, EQNX is uniquely positioned to be your partner of choice in your control-optimization journey