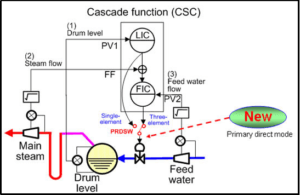

The figure shows a typical drum level controller, which measures the drum level(1), main steam flow (2), and feed flow (3) and manipulates the feed control valve to regulate the drum level. This is three-element control.

What is the need for three-element control?

In the medium to high-pressure boilers, the cost of building and installing large steam drums forced the reduction of the drum size for a given steam production capacity. The consequence of smaller drum size is an attendant reduction in process time constants or the speed with which important process variables can change. Smaller time constants mean upsets must be addressed more quickly.

The Boiler drum liquid level must remain low enough to guarantee that there is adequate disengaging volume above the liquid and high enough to assure that there is present in every steam generating tube in the boiler. These requirements typically result in a narrow range in which the liquid level must be maintained. The feed used to maintain the liquid level in industrial boilers often comes from multiple sources and is brought up to steam drum pressure by pumps operating in parallel. With multiple sources and multiple pumps, the supply pressure of the feed will change over time. Every time supply pressure changes, the flow rate through the valve, even if it remains fixed in position, is immediately affected. Concerning the above needs, the sophisticated control strategies called three-element Drum Level control were developed.